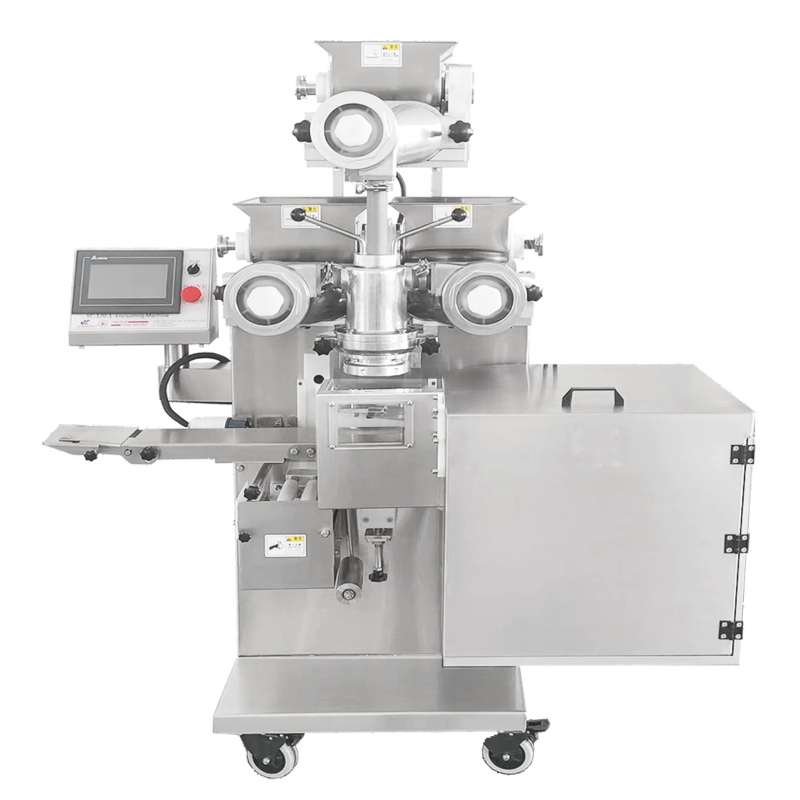

automatic pastry making machine

The automatic pastry making machine represents a revolutionary advancement in commercial baking technology, transforming how bakeries, restaurants, and food production facilities create high-quality pastries. This sophisticated equipment streamlines the entire pastry production process, from mixing and shaping to baking and finishing. The automatic pastry making machine combines precision engineering with user-friendly controls, enabling operators to produce consistent, professional-grade pastries with minimal manual intervention. These machines incorporate advanced mixing systems that ensure optimal dough consistency and texture development. The integrated temperature control mechanisms maintain precise thermal conditions throughout the production cycle, guaranteeing uniform results every batch. Modern automatic pastry making machine units feature programmable settings that allow operators to store multiple recipes and adjust parameters such as mixing time, speed, and ingredient ratios. The production capacity of these machines varies significantly, with models available for small bakeries producing hundreds of pastries daily to industrial-scale operations handling thousands of units per hour. Key technological features include servo-driven motors for precise control, stainless steel construction for hygiene and durability, and intuitive touchscreen interfaces for easy operation. Many automatic pastry making machine models incorporate multi-stage mixing capabilities, allowing for complex pastry preparations requiring different mixing speeds and techniques. The equipment typically includes automated ingredient dispensing systems that measure and add components with exceptional accuracy, eliminating human error and ensuring consistent flavor profiles. Safety features are paramount in these machines, with emergency stops, protective guards, and automated shutdown protocols preventing accidents during operation. The versatility of the automatic pastry making machine extends to various pastry types, including croissants, Danish pastries, puff pastries, and specialty items, making it an invaluable asset for diverse commercial operations seeking to expand their product offerings while maintaining quality standards.