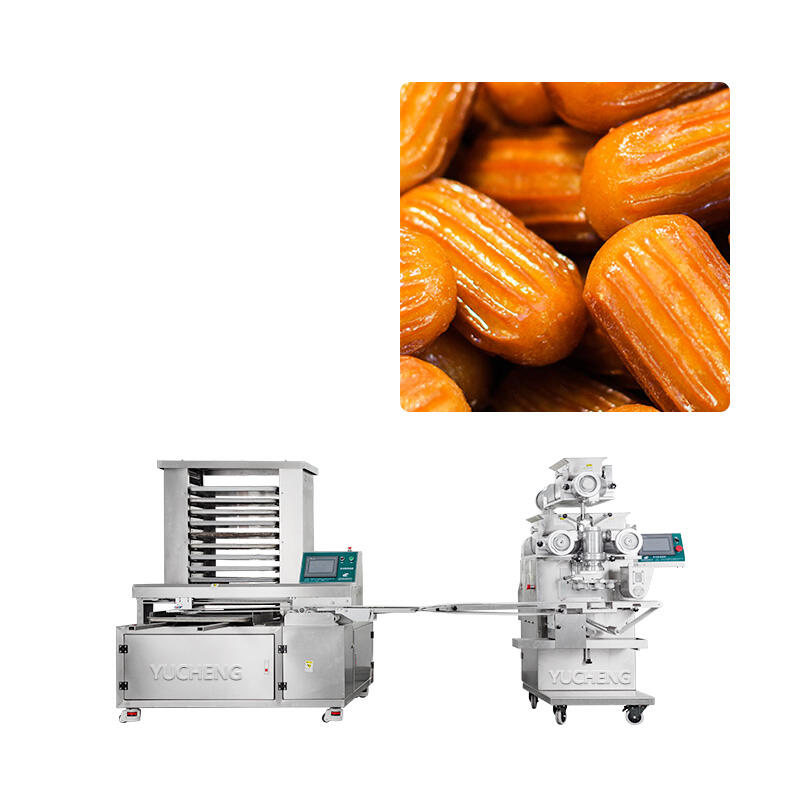

kubba machine for sale

The kubba machine for sale represents a revolutionary advancement in Middle Eastern food preparation technology, specifically designed to streamline the production of traditional kubba, kibbeh, and similar stuffed dumplings. This state-of-the-art equipment features a precise automated system that expertly shapes and fills these popular delicacies with consistent quality and efficiency. The machine incorporates advanced stainless steel construction, ensuring durability and compliance with food safety standards, while its innovative design allows for adjustable thickness control and various filling options. The equipment's user-friendly interface enables operators to easily program and monitor production parameters, including portion size, filling ratio, and production speed. With a production capacity ranging from 1,200 to 2,400 pieces per hour, this machine significantly reduces labor costs while maintaining traditional taste and texture. The system includes multiple forming dies for different kubba shapes and sizes, an automatic filling mechanism, and a precision cutting system that ensures uniform results. Additionally, the machine features easy-to-clean components, reducing maintenance time and ensuring optimal hygiene standards.