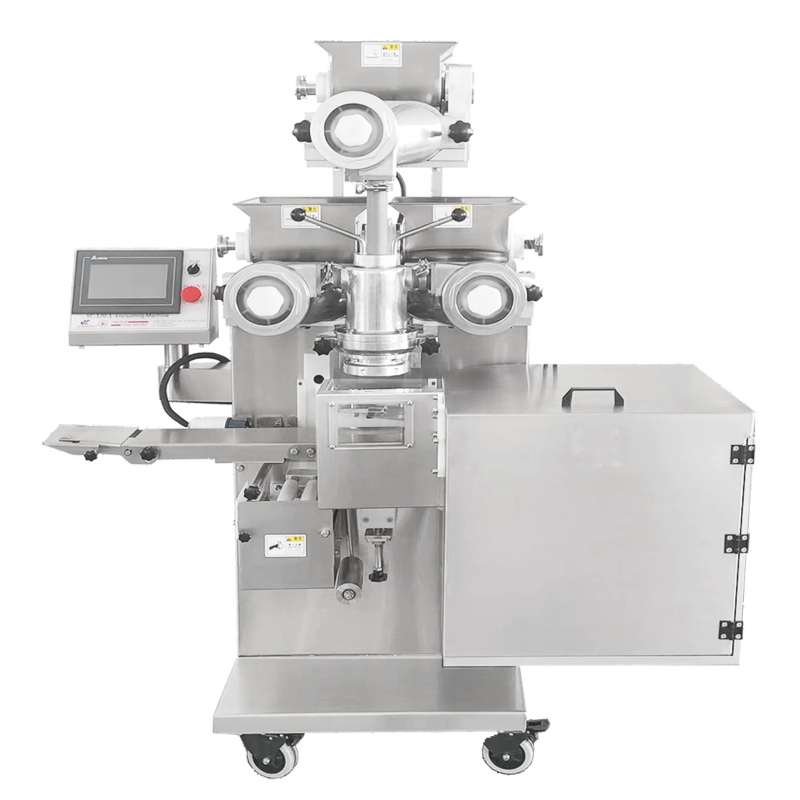

chocolate chip cookie making machine

The chocolate chip cookie making machine represents a revolutionary advancement in commercial baking technology, designed to streamline the production of one of the world's most beloved treats. This sophisticated equipment combines precision engineering with user-friendly operation to deliver consistent, high-quality chocolate chip cookies at scale. The chocolate chip cookie making machine integrates multiple production stages into a single, efficient system that handles everything from dough preparation to final packaging. At its core, the machine features an automated mixing system that precisely combines flour, butter, sugar, eggs, and other ingredients according to pre-programmed recipes. The integrated chocolate chip dispenser ensures uniform distribution throughout each cookie, maintaining consistent taste and texture across every batch. Temperature control systems monitor and adjust baking conditions in real-time, while conveyor belts transport cookies through each production phase seamlessly. The machine's touchscreen interface allows operators to modify recipes, adjust production speeds, and monitor quality parameters with minimal training required. Advanced sensors detect irregularities in dough consistency, baking temperature, and cookie size, automatically making corrections to maintain product standards. The chocolate chip cookie making machine incorporates food-grade stainless steel construction that meets international hygiene standards, featuring easy-clean surfaces and removable components for thorough sanitization. Production capacity ranges from small bakery operations producing hundreds of cookies per hour to industrial-scale facilities manufacturing thousands daily. The machine's modular design allows customization based on specific production requirements, space constraints, and budget considerations. Energy-efficient motors and heating elements reduce operational costs while maintaining optimal performance levels. Quality control features include weight monitoring, visual inspection systems, and automated rejection of substandard products. The chocolate chip cookie making machine supports various cookie sizes, thicknesses, and chocolate chip densities, providing flexibility for different market segments and consumer preferences.