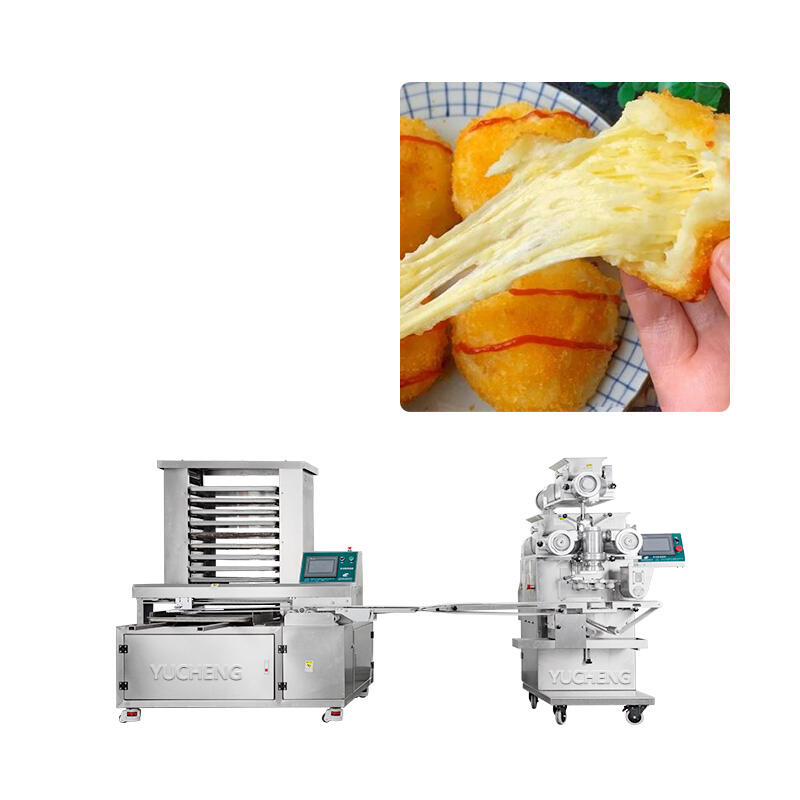

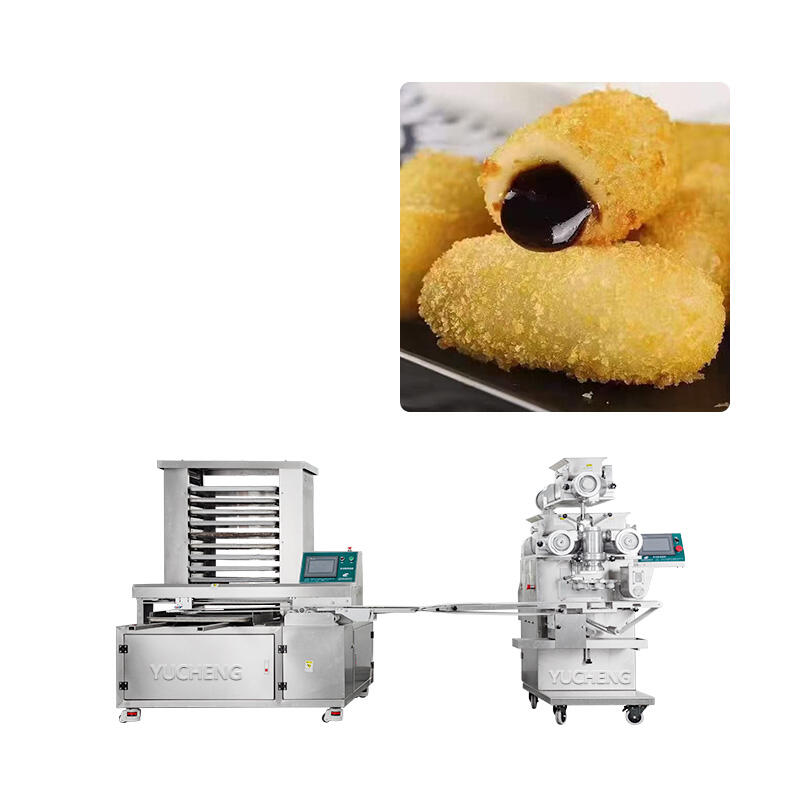

frozen kubba machine

The frozen kubba machine represents a groundbreaking advancement in food processing technology, specifically designed to automate and streamline the production of traditional Middle Eastern kubba. This sophisticated equipment combines precision engineering with modern automation to transform the labor-intensive process of kubba making into an efficient, high-volume operation. The machine features a state-of-the-art filling system that carefully layers the outer shell mixture with the seasoned meat filling, ensuring consistent quality and uniform shape in every piece. Operating at optimal temperatures, it maintains the integrity of ingredients while forming perfectly shaped kubba at commercial volumes. The machine's innovative design includes adjustable settings for size and filling ratios, allowing producers to customize their products according to specific market demands. With integrated cooling systems, it can process and freeze products in a continuous operation, significantly reducing production time and labor costs. The automated cleaning and sanitizing features ensure compliance with food safety standards, while the user-friendly interface makes it accessible for operators of varying skill levels. This machine has revolutionized kubba production, making it possible for food manufacturers to meet increasing market demand while maintaining traditional taste and quality standards.