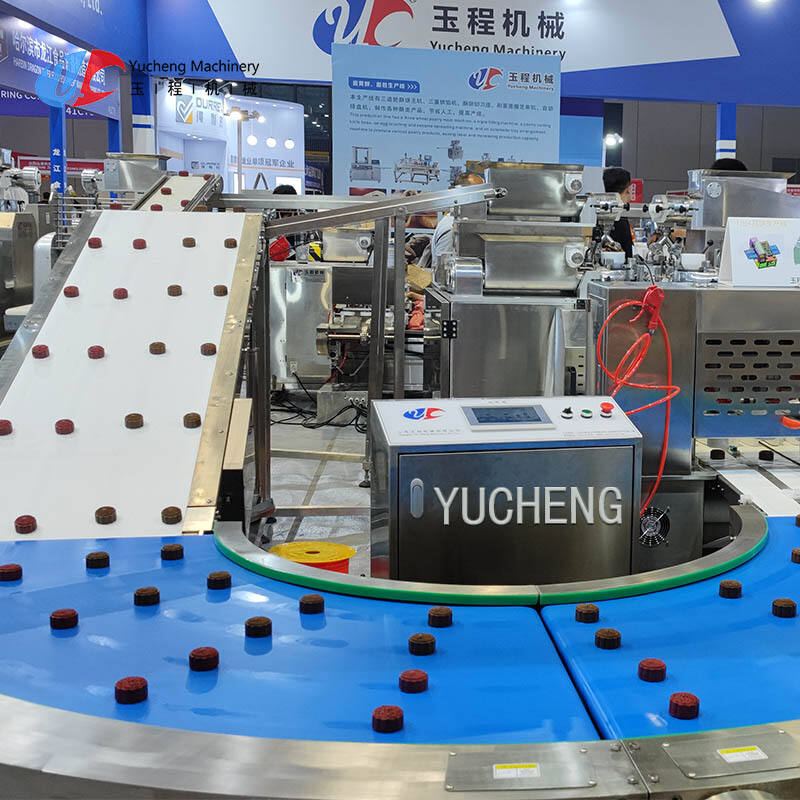

date bar making machine

The date bar making machine is a sophisticated piece of equipment designed to efficiently produce high-quality date bars through an automated process. This innovative machine combines precision engineering with modern technology to transform raw date paste into uniformly shaped, perfectly textured snack bars. The system features a continuous feed mechanism that ensures consistent production flow, complete with automated mixing, forming, cutting, and cooling capabilities. The machine's stainless steel construction guarantees food safety and durability, while its advanced temperature control system maintains optimal processing conditions throughout operation. It can handle various date varieties and accommodate additional ingredients such as nuts, seeds, or dried fruits, making it versatile for different product formulations. The production line includes multiple stations: ingredient feeding, mixing, forming, cutting, and cooling, all synchronized for maximum efficiency. With adjustable speed controls and precise measurement systems, operators can easily modify production parameters to meet specific requirements. The machine's user-friendly interface allows for simple operation and monitoring, while its compact design optimizes floor space usage. Safety features include emergency stop buttons, protective guards, and automatic shut-off mechanisms, ensuring operator safety and product quality.