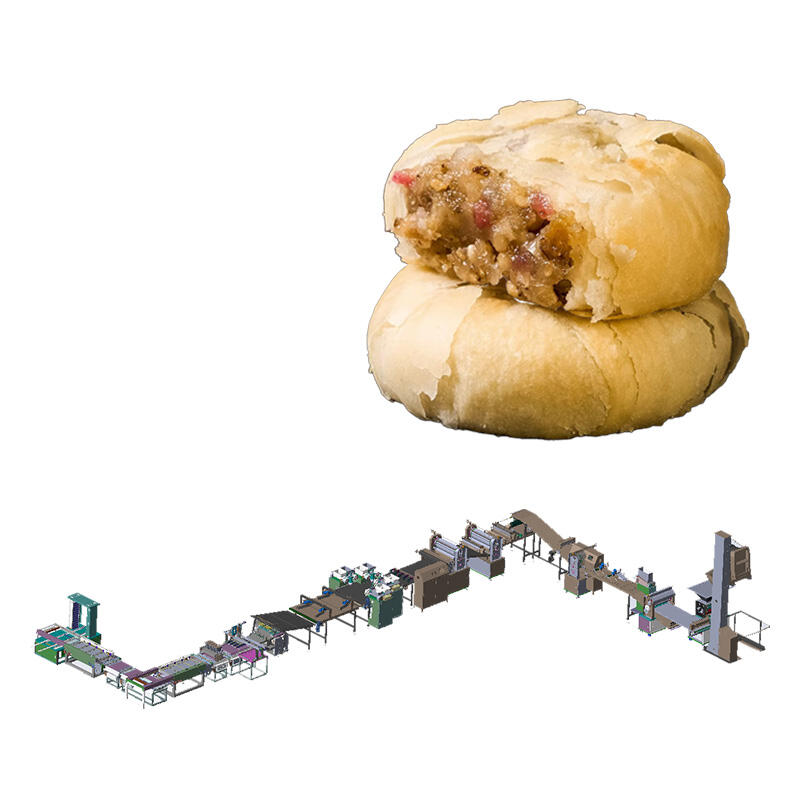

Advanced Automation System

The date ball making machines cutting-edge automation system represents a significant leap forward in food processing technology. This system incorporates precise sensors and sophisticated control algorithms that work in harmony to ensure consistent production quality. The automated process begins with raw date input and progresses through multiple stages, including mixing, forming, and finishing, with minimal human intervention. The system monitors and adjusts parameters in real-time, including temperature, pressure, and forming speed, to maintain optimal production conditions. This level of automation not only increases productivity but also significantly reduces the possibility of human error, resulting in superior product consistency. The system can be programmed to handle different recipes and product specifications, offering flexibility while maintaining strict quality control standards.