date ball forming machine price

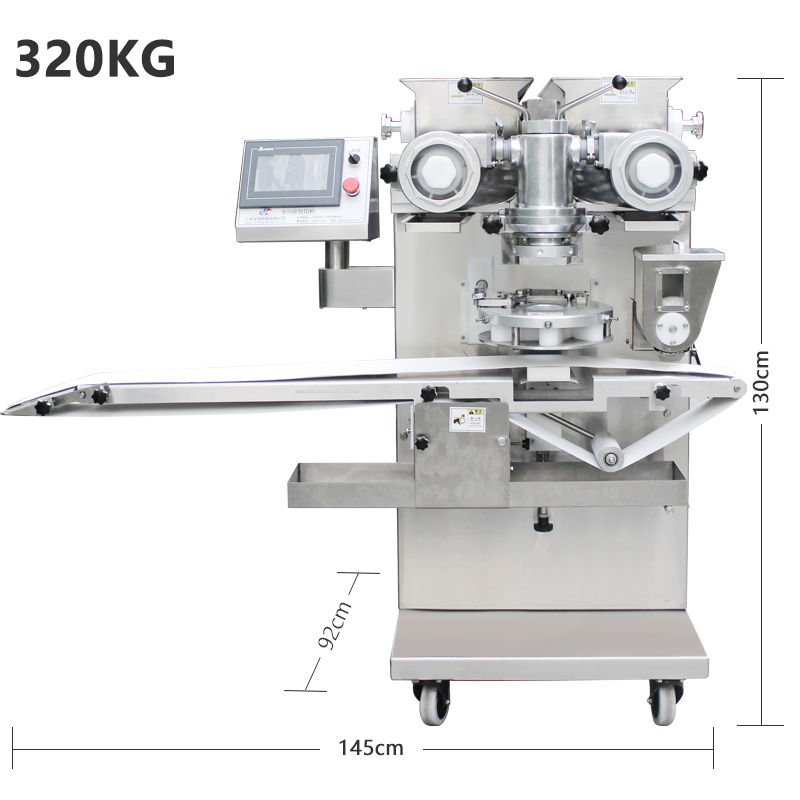

The date ball forming machine price represents a crucial investment consideration for businesses in the food processing industry. This specialized equipment, designed for efficient date processing, combines precision engineering with cost-effective operation. The machine's primary function involves transforming date paste into uniformly shaped balls, offering production rates of 1,000 to 3,000 pieces per hour, depending on the model and specifications. The technology incorporates advanced features such as adjustable size controls, allowing manufacturers to produce date balls ranging from 2-5cm in diameter. The machine typically includes stainless steel construction, meeting food-grade standards, with automated temperature control systems to maintain optimal processing conditions. Applications extend beyond traditional date ball production to include various dried fruit processing capabilities, making it versatile for diverse food manufacturing needs. The price range varies significantly based on capacity, automation level, and additional features, typically ranging from $5,000 to $15,000. This investment considers factors such as production scale, energy efficiency, and maintenance requirements, making it essential for businesses to evaluate their specific needs against available options.