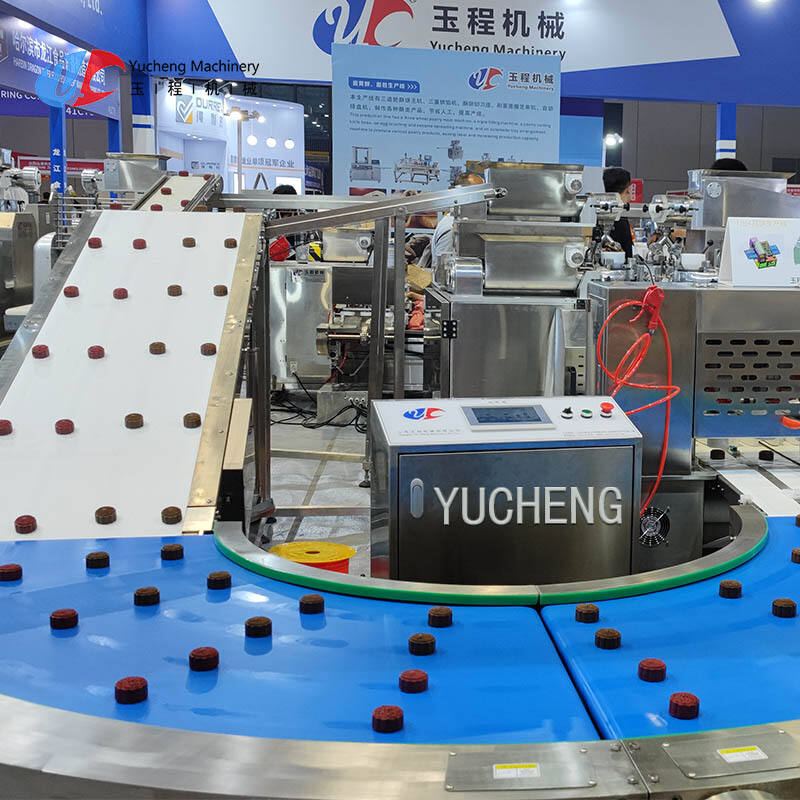

date ball forming machine

The date ball forming machine represents a revolutionary advancement in food processing technology, specifically designed to transform date paste into uniformly shaped spherical products. This sophisticated equipment combines precision engineering with automated functionality to deliver consistent, high-quality date balls suitable for commercial production. The machine features a specially designed roller system that precisely measures and shapes date paste into perfectly rounded balls, while maintaining the natural texture and nutritional properties of the dates. Operating at optimized speeds of up to 100 pieces per minute, it incorporates advanced control systems that ensure precise weight measurement and size consistency. The machine's food-grade stainless steel construction guarantees hygiene standards while providing durability in industrial settings. Its versatile design accommodates various date varieties and can be adjusted to produce different ball sizes ranging from 2-5 centimeters in diameter. The integrated temperature control system maintains optimal processing conditions, preventing the date paste from sticking or losing its desired consistency during formation. This equipment has become essential in modern date processing facilities, confectionery manufacturing, and health food production lines, offering efficient automation for traditional date-based products.