The global dessert industry has witnessed a remarkable transformation with the introduction of innovative frozen treats that combine traditional Japanese techniques with modern manufacturing capabilities. Among these revolutionary developments, the mochi ice cream machine has emerged as a game-changing piece of equipment that enables businesses to create perfectly crafted mochi ice cream products consistently and efficiently. This sophisticated machinery represents the perfect fusion of ancient culinary artistry and cutting-edge technology, allowing manufacturers to meet the growing consumer demand for premium frozen desserts that offer unique textures and flavors.

Revolutionary Technology Behind Modern Mochi Production

Advanced Manufacturing Capabilities

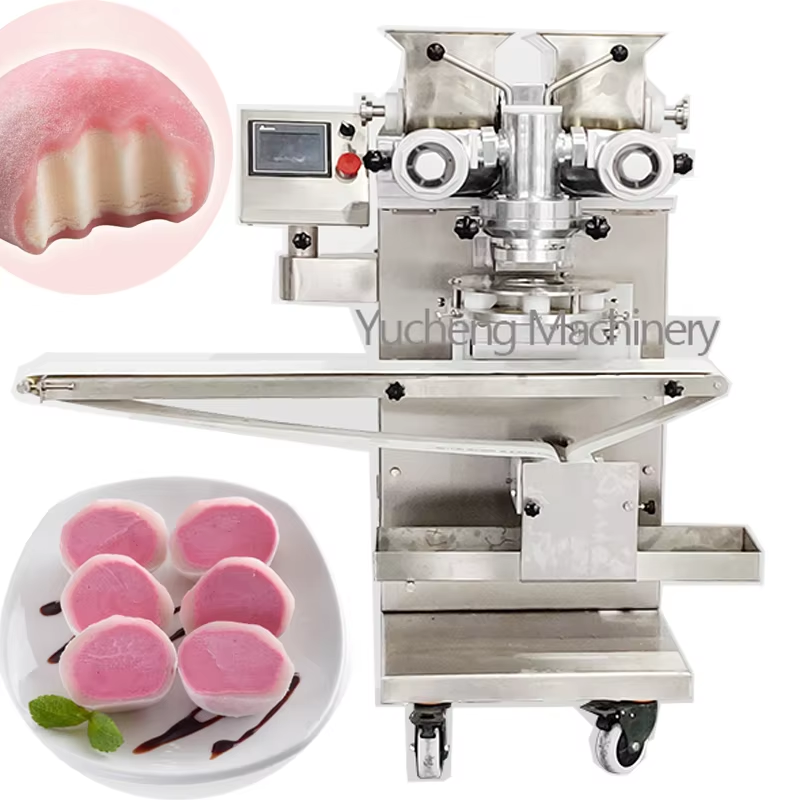

The contemporary mochi ice cream machine incorporates state-of-the-art engineering principles that ensure precise temperature control, consistent dough thickness, and uniform product quality. These machines utilize sophisticated pneumatic systems and programmable logic controllers that maintain optimal operating conditions throughout the production process. The integration of digital monitoring systems allows operators to track critical parameters such as dough consistency, filling distribution, and wrapping precision, ensuring that every mochi ice cream unit meets stringent quality standards.

Modern mochi ice cream machine designs feature multiple stations that handle different aspects of the production process simultaneously, including dough preparation, ice cream portioning, wrapping, and sealing operations. The automated nature of these systems significantly reduces manual labor requirements while increasing production capacity and maintaining consistent product quality. Advanced models can produce hundreds of units per hour, making them ideal for commercial operations ranging from small artisanal shops to large-scale manufacturing facilities.

Precision Engineering and Quality Control

The mechanical precision built into each mochi ice cream machine ensures that every product maintains the characteristic soft, chewy texture of traditional mochi while perfectly encasing the frozen ice cream center. These machines employ specialized forming mechanisms that create uniform dough sheets of optimal thickness, preventing cracking during the wrapping process and ensuring proper sealing to maintain product integrity during storage and distribution.

Quality control systems integrated into modern equipment include automated inspection processes that detect irregularities in shape, size, or sealing quality. These systems can automatically reject defective products, ensuring that only perfectly formed mochi ice cream reaches consumers. The combination of mechanical precision and automated quality control makes the mochi ice cream machine an indispensable tool for maintaining consistent product excellence in commercial production environments.

Market Demand and Consumer Preferences

Growing Popularity of Asian-Inspired Desserts

The increasing popularity of mochi ice cream has created substantial demand for efficient production equipment capable of meeting commercial volume requirements. Consumer interest in authentic Asian desserts has grown exponentially as food culture becomes more globalized, driving retailers and manufacturers to seek reliable mochi ice cream machine solutions that can produce high-quality products consistently. This trend reflects broader changes in consumer preferences toward unique textural experiences and premium frozen dessert options.

Market research indicates that mochi ice cream sales have experienced double-digit growth rates in numerous international markets, particularly in North America and Europe. This surge in demand has prompted food manufacturers to invest in specialized production equipment that can handle the unique requirements of mochi production while maintaining the delicate balance between the soft outer shell and frozen inner core that defines quality mochi ice cream products.

Premium Product Positioning and Profit Margins

The premium positioning of mochi ice cream in the frozen dessert market creates attractive profit opportunities for manufacturers equipped with proper production machinery. A reliable mochi ice cream machine enables producers to capitalize on higher retail prices while maintaining reasonable production costs through efficient automation and consistent quality output. The unique nature of mochi ice cream allows for premium pricing strategies that significantly exceed conventional ice cream products.

Commercial success in the mochi ice cream market depends heavily on production consistency and quality control, factors that are directly influenced by the capabilities of the manufacturing equipment used. Businesses that invest in high-quality mochi ice cream machine technology position themselves to capture market share in this rapidly growing segment while building brand reputation for product excellence and reliability.

Technical Specifications and Performance Features

Production Capacity and Efficiency Metrics

Modern mochi ice cream machine models are engineered to deliver impressive production rates while maintaining energy efficiency and operational reliability. These machines typically feature variable speed controls that allow operators to adjust production rates based on demand requirements and product specifications. High-end models can achieve production rates exceeding 3000 units per hour, making them suitable for large-scale commercial operations and contract manufacturing applications.

The efficiency of a mochi ice cream machine extends beyond simple production speed to encompass material utilization, energy consumption, and waste reduction. Advanced models incorporate recycling systems that capture and reuse excess dough material, minimizing waste and reducing raw material costs. These efficiency improvements contribute significantly to the overall profitability of mochi ice cream production operations.

Temperature Control and Product Integrity

Precise temperature management represents one of the most critical aspects of mochi ice cream machine operation, as the equipment must maintain optimal conditions for both the mochi dough and ice cream components throughout the production process. Advanced refrigeration systems integrated into modern machines ensure that ice cream maintains proper consistency while preventing the mochi wrapper from becoming too soft or difficult to handle during forming operations.

The temperature control systems in professional-grade mochi ice cream machine units utilize multiple zones with independent climate control, allowing operators to optimize conditions for each stage of the production process. This sophisticated approach to thermal management ensures consistent product quality and extends the shelf life of finished products by maintaining proper crystalline structures in both components.

Economic Benefits and Return on Investment

Cost Reduction Through Automation

Investment in automated mochi ice cream machine technology delivers substantial cost savings through reduced labor requirements and improved production efficiency. Manual mochi production requires skilled workers and significant time investment per unit, making automated equipment essential for achieving competitive production costs. The labor savings alone often justify the equipment investment within the first year of operation for businesses with moderate production volumes.

Beyond direct labor cost reductions, mochi ice cream machine automation eliminates variability in production quality and timing that characterizes manual production methods. This consistency translates to reduced waste, fewer quality control issues, and improved customer satisfaction, all of which contribute to enhanced profitability and business sustainability in competitive market conditions.

Scalability and Business Growth Opportunities

The scalability offered by modern mochi ice cream machine technology enables businesses to expand production capacity without proportional increases in facility requirements or workforce. Modular equipment designs allow for incremental capacity additions as market demand grows, providing flexibility for businesses to match production capabilities with market opportunities effectively.

Investment in reliable mochi ice cream machine equipment also opens opportunities for contract manufacturing and private label production, diversifying revenue streams and maximizing equipment utilization. The consistent quality and production capacity provided by automated equipment make businesses attractive partners for retailers and food service companies seeking reliable suppliers of premium frozen dessert products.

Maintenance and Operational Considerations

Preventive Maintenance Programs

Successful operation of any mochi ice cream machine requires comprehensive preventive maintenance programs that ensure consistent performance and extend equipment lifespan. These programs typically include daily cleaning procedures, weekly lubrication schedules, and monthly inspection routines that identify potential issues before they impact production operations. Proper maintenance protocols are essential for maintaining food safety standards and preventing costly breakdowns during peak production periods.

Modern mochi ice cream machine designs incorporate diagnostic systems that monitor equipment performance and alert operators to maintenance requirements or potential problems. These predictive maintenance capabilities help minimize unexpected downtime and ensure that production schedules remain on track, which is particularly important for businesses with time-sensitive delivery commitments or seasonal production demands.

Operator Training and Safety Protocols

Effective operation of mochi ice cream machine equipment requires properly trained personnel who understand both the technical aspects of the machinery and the food safety requirements of commercial production. Comprehensive training programs cover equipment operation, safety procedures, quality control protocols, and troubleshooting techniques that enable operators to maximize productivity while maintaining safe working conditions.

Safety considerations for mochi ice cream machine operation include proper handling of cryogenic refrigeration systems, mechanical safety protocols for moving equipment components, and food safety procedures that prevent contamination during production processes. Well-trained operators are essential for maintaining insurance compliance, regulatory adherence, and overall operational efficiency in commercial production environments.

Future Trends and Innovation Opportunities

Emerging Technologies and Smart Manufacturing

The future development of mochi ice cream machine technology will likely incorporate artificial intelligence and machine learning capabilities that optimize production parameters based on real-time quality feedback and historical performance data. These smart manufacturing approaches promise to further improve product consistency while reducing waste and energy consumption through predictive optimization of operating conditions.

Integration with Internet of Things platforms will enable remote monitoring and control of mochi ice cream machine operations, allowing manufacturers to optimize production efficiency across multiple facilities and provide enhanced technical support services. These connectivity features will become increasingly important as manufacturers seek to maximize operational efficiency and minimize downtime in competitive market conditions.

Sustainability and Environmental Considerations

Environmental sustainability considerations are driving innovation in mochi ice cream machine design, with manufacturers developing more energy-efficient refrigeration systems and incorporating recyclable materials in equipment construction. These sustainability improvements align with growing consumer and regulatory pressure for environmentally responsible manufacturing practices throughout the food industry.

Future mochi ice cream machine models will likely incorporate advanced waste heat recovery systems and renewable energy integration capabilities that reduce overall environmental impact while maintaining production efficiency. These environmental considerations are becoming increasingly important factors in equipment purchasing decisions as businesses seek to demonstrate corporate social responsibility commitments.

FAQ

How much space does a commercial mochi ice cream machine require for installation?

Commercial mochi ice cream machine installations typically require between 200-400 square feet of floor space, depending on the production capacity and specific model configuration. This space requirement includes clearance areas for maintenance access, material handling, and safety compliance. Additional space may be needed for auxiliary equipment such as ingredient preparation stations, packaging areas, and refrigerated storage units.

What are the typical production costs per unit when using automated mochi ice cream machine equipment?

Production costs for mochi ice cream using automated equipment typically range from $0.25 to $0.75 per unit, depending on ingredient quality, production volume, and local labor costs. These costs include raw materials, energy consumption, labor, and equipment depreciation. Higher production volumes generally result in lower per-unit costs due to improved efficiency and fixed cost distribution across larger output quantities.

How long does it take to train operators for mochi ice cream machine operation?

Basic operator training for mochi ice cream machine equipment typically requires 1-2 weeks of intensive instruction covering equipment operation, safety procedures, and quality control protocols. Advanced troubleshooting and maintenance training may require additional weeks depending on the complexity of the equipment and the operator's prior experience with similar manufacturing equipment. Ongoing refresher training is recommended to maintain optimal performance standards.

What maintenance intervals are recommended for optimal mochi ice cream machine performance?

Recommended maintenance schedules for mochi ice cream machine equipment include daily cleaning and inspection routines, weekly lubrication procedures, monthly comprehensive inspections, and annual major service intervals. Critical components such as refrigeration systems may require more frequent attention, while mechanical components typically follow standard industrial maintenance intervals. Following manufacturer-recommended maintenance schedules is essential for maintaining warranty coverage and optimal equipment performance.

Table of Contents

- Revolutionary Technology Behind Modern Mochi Production

- Market Demand and Consumer Preferences

- Technical Specifications and Performance Features

- Economic Benefits and Return on Investment

- Maintenance and Operational Considerations

- Future Trends and Innovation Opportunities

-

FAQ

- How much space does a commercial mochi ice cream machine require for installation?

- What are the typical production costs per unit when using automated mochi ice cream machine equipment?

- How long does it take to train operators for mochi ice cream machine operation?

- What maintenance intervals are recommended for optimal mochi ice cream machine performance?