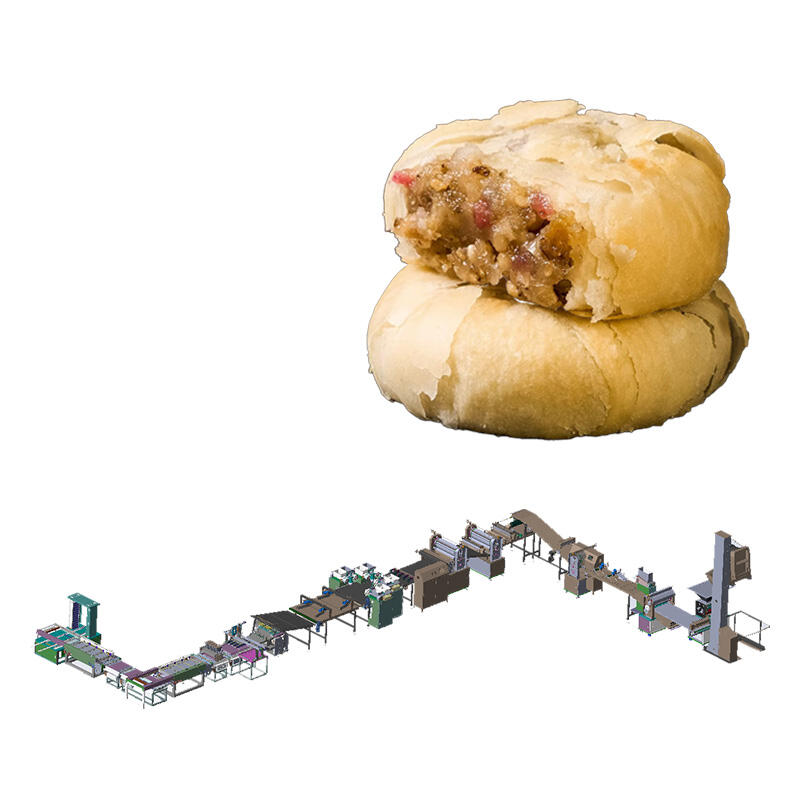

pastry making machine

The pastry making machine represents a significant advancement in commercial baking technology, combining precision engineering with versatile functionality to streamline the production of various pastry products. This sophisticated equipment features a robust stainless steel construction and incorporates multiple automated systems designed to handle different aspects of pastry preparation. The machine's core functions include dough mixing, sheeting, folding, and cutting, all controlled through an intuitive digital interface that ensures consistency in production. With adjustable speed settings and programmable operations, it can accommodate various dough types and recipes, from delicate croissants to sturdy pie crusts. The machine's advanced temperature control system maintains optimal conditions throughout the production process, while its integrated safety features protect operators during operation. Modern pastry making machines often include features such as automatic ingredient dispensing, precise thickness control, and multiple cutting patterns to create diverse pastry shapes. These machines are designed to meet both industrial production demands and artisanal baking requirements, offering scalability and flexibility in output capacity.