date bar maker machine price

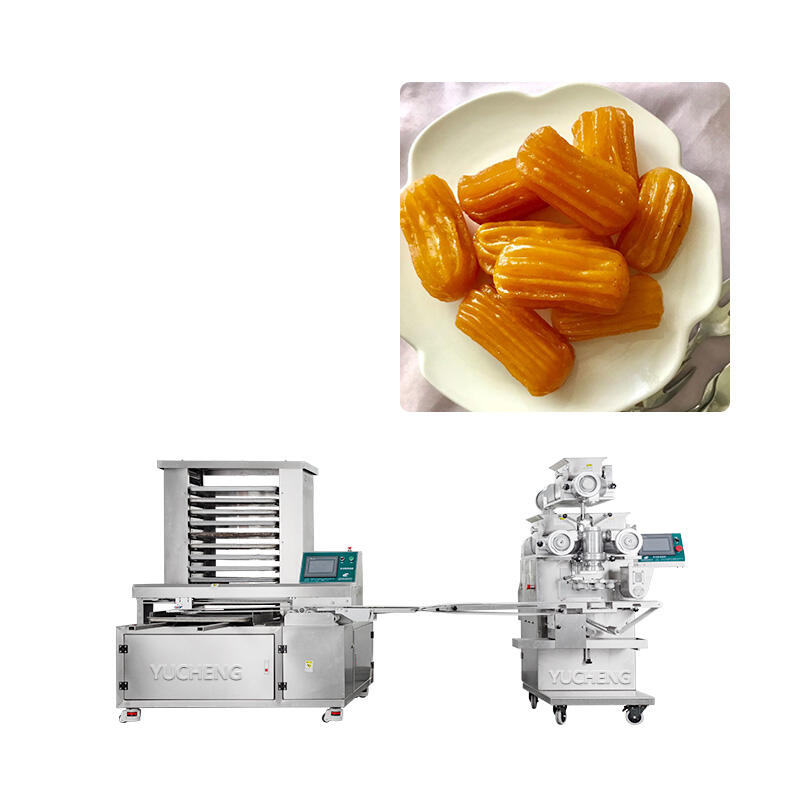

The date bar maker machine price represents a significant investment consideration for businesses in the food processing industry. This advanced equipment, available across various price points ranging from $5,000 to $25,000, offers comprehensive solutions for date bar production. The machine incorporates state of the art technology, featuring automated systems for mixing, forming, and cutting date bars with precision. These machines typically process 100 to 500 kg per hour, depending on the model and price point. The price variation reflects differences in production capacity, automation level, and additional features such as temperature control systems and digital interfaces. Higher end models include PLC control systems, stainless steel construction, and advanced safety features. The machine's versatility extends beyond date bars, allowing for the production of various fruit based snacks. Energy efficiency features help optimize operational costs, while easy clean designs reduce maintenance time. The price also typically includes installation support, warranty coverage, and basic operator training. For businesses scaling their production, manufacturers often offer flexible payment terms and leasing options to make acquisition more manageable.