small date bar machine

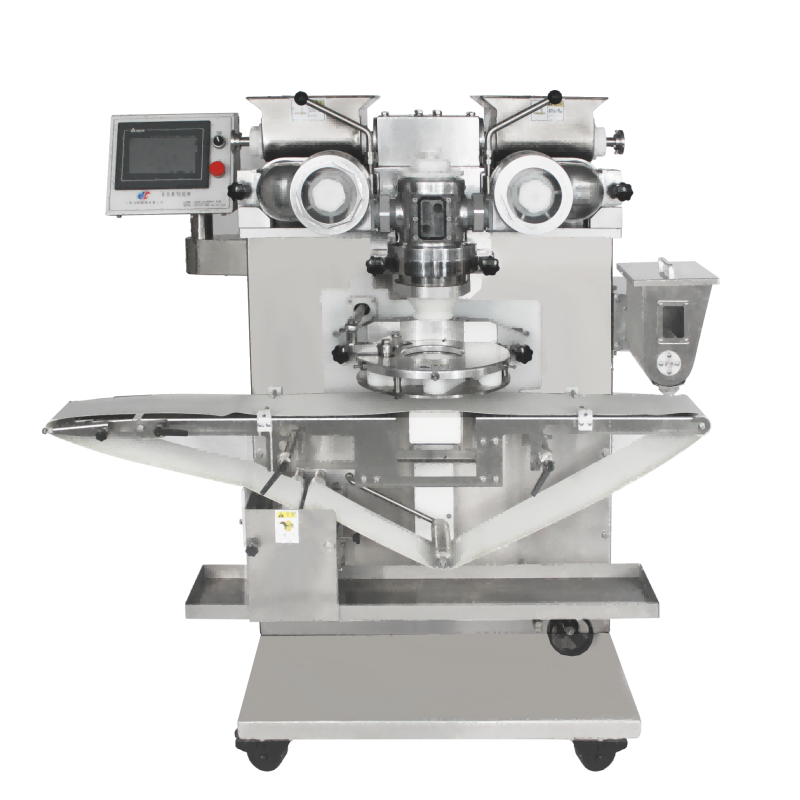

The small date bar machine represents a significant advancement in food processing technology, specifically designed for efficient date processing and forming operations. This compact yet powerful equipment transforms raw dates into uniformly shaped bars through a sophisticated mechanical process. The machine features a precision feeding system, advanced temperature control mechanisms, and adjustable pressure settings to ensure consistent product quality. Its stainless steel construction meets strict hygiene standards while providing durability for long-term operation. The system incorporates automated controls for precise timing and pressure application, resulting in uniform date bars with consistent texture and appearance. The machine's versatility allows for various size adjustments, making it suitable for different product specifications. Its user-friendly interface enables operators to easily modify parameters such as compression force, bar thickness, and cutting length. The small date bar machine also includes safety features such as emergency stop buttons and protective guards. With a production capacity tailored for small to medium-scale operations, this machine proves ideal for artisanal producers and medium-sized food processing facilities. The integrated cleaning system facilitates maintenance and ensures compliance with food safety regulations.