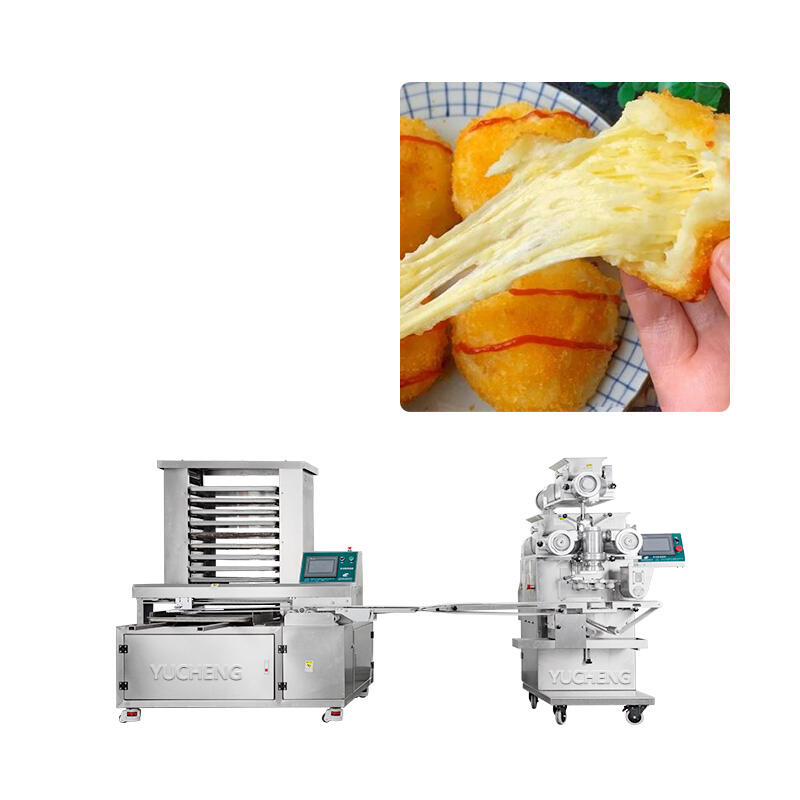

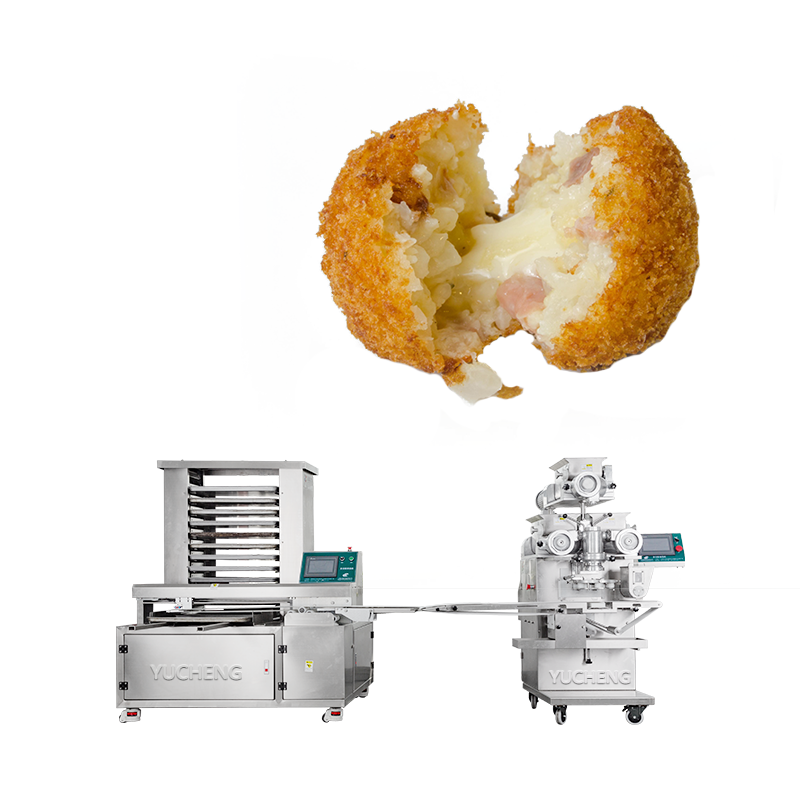

cheapest kubba making forming machine

The cheapest kubba making forming machine represents an economical solution for businesses looking to automate their traditional Middle Eastern food production. This efficient machine combines simplicity with functionality, capable of producing perfectly shaped kubba at a rate of 1200-1500 pieces per hour. The machine features a stainless steel construction that ensures durability and compliance with food safety standards, while maintaining a competitive price point. It operates through a straightforward mechanical system that forms the outer shell and stuffing simultaneously, creating consistent kubba shapes every time. The machine includes adjustable settings for shell thickness and filling quantity, allowing for customization based on specific recipe requirements. Its compact design makes it suitable for small to medium-sized food production facilities, restaurants, and catering services. The machine's user-friendly interface requires minimal training, making it accessible to operators of various skill levels. Despite its affordable price tag, it incorporates essential safety features and easy-to-clean components, ensuring both operator safety and proper sanitation. The machine can handle different types of dough consistencies and filling mixtures, providing versatility in production options.