Revolutionizing Traditional Meat Processing with Modern Technology

The food processing industry has witnessed remarkable technological advancements, and the kubba machine stands as a testament to this evolution. This innovative equipment has transformed the way meat processing facilities and commercial kitchens handle the preparation of traditional Middle Eastern dishes, particularly the beloved kubba. By automating the complex process of mixing, grinding, and forming meat mixtures, the kubba machine delivers consistency, efficiency, and quality at an unprecedented scale.

Understanding the Kubba Machine Technology

Core Components and Functionality

At the heart of the kubba machine lies a sophisticated system of precision-engineered components. The main chamber features a powerful motor that drives the mixing and grinding mechanisms, ensuring thorough incorporation of ingredients. The specially designed forming plates create the characteristic shell and cavity of traditional kubba, while maintaining the perfect thickness and texture that consumers expect.

The machine's advanced control panel allows operators to adjust various parameters, including mixing speed, grinding consistency, and portion size. This level of customization ensures that different recipes and specifications can be accommodated with minimal effort, making the kubba machine an incredibly versatile tool in any food processing operation.

Advanced Features and Safety Mechanisms

Modern kubba machines come equipped with state-of-the-art safety features that protect both operators and the quality of the final product. Emergency stop buttons, overload protection, and automatic shut-off systems ensure safe operation during high-volume production runs. The food-grade stainless steel construction maintains hygiene standards while resisting corrosion and wear.

The integration of digital displays and programmable settings allows for precise control over the production process. These features enable operators to save and recall specific recipes, ensuring consistency across multiple batches and reducing the learning curve for new staff members.

Operational Benefits and Production Efficiency

Streamlined Production Process

The implementation of a kubba machine dramatically transforms the traditional manual preparation method into a streamlined, efficient operation. What once took hours of manual labor can now be accomplished in a fraction of the time, with significantly reduced physical strain on workers. The machine's continuous operation capability enables facilities to meet high-volume demands without compromising on quality or consistency.

Production schedules become more predictable and manageable, as the kubba machine maintains a consistent output rate. This reliability allows businesses to better plan their operations, manage inventory, and respond to fluctuating market demands with greater agility.

Cost Reduction and Resource Optimization

The financial benefits of incorporating a kubba machine extend beyond mere labor savings. The precision of the machine significantly reduces ingredient waste, as portions are perfectly measured and formed every time. The consistency in product size and weight helps maintain accurate cost calculations and pricing strategies.

Additionally, the machine's efficient operation leads to reduced energy consumption compared to multiple smaller appliances performing separate tasks. The consolidated production process also requires less workspace, allowing businesses to optimize their facility layout and potentially reduce overhead costs.

Quality Control and Product Consistency

Maintaining Traditional Authenticity

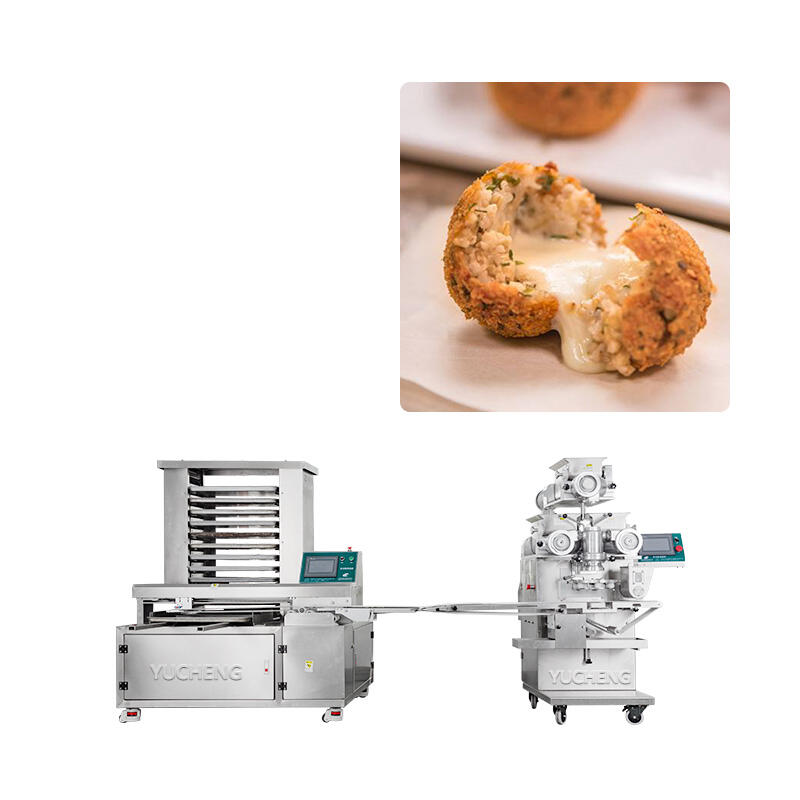

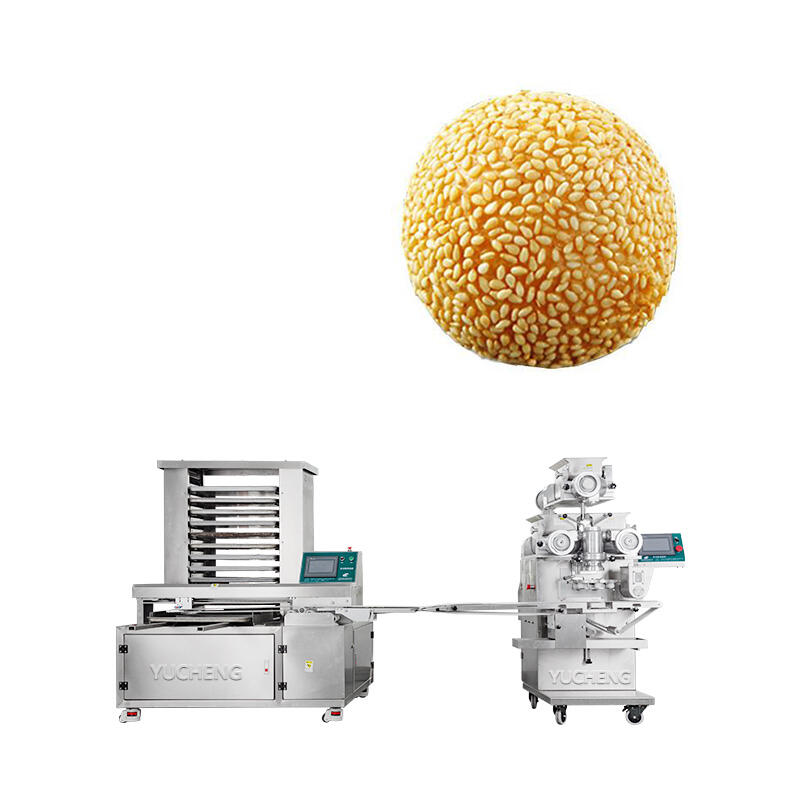

Despite its modern approach, the kubba machine preserves the authentic characteristics of traditionally prepared kubba. The carefully engineered forming mechanisms replicate the thickness, texture, and appearance that consumers associate with handmade products. This balance between efficiency and authenticity has made the kubba machine an invaluable tool for businesses looking to scale their operations while maintaining product quality.

The consistent pressure and temperature control during the forming process ensures that each piece meets the exact specifications required for proper cooking and serving. This reliability helps businesses maintain their reputation for quality and satisfy customer expectations.

Food Safety and Hygiene Standards

Modern kubba machines are designed with food safety as a primary consideration. The smooth, non-porous surfaces and easily dismantled components facilitate thorough cleaning and sanitization. The reduction in human handling also minimizes the risk of contamination, helping businesses maintain compliance with food safety regulations.

Regular maintenance schedules are simplified thanks to the machine's modular design, allowing for quick inspection and cleaning of critical components. This proactive approach to hygiene management helps prevent potential food safety issues and extends the equipment's operational life.

Future Trends and Industry Impact

Technological Advancements

The evolution of kubba machine technology continues to accelerate, with manufacturers incorporating IoT capabilities and smart features into newer models. These advancements enable remote monitoring, predictive maintenance, and data-driven optimization of production processes. The integration of artificial intelligence may soon allow for even greater automation and efficiency improvements.

Future developments may include enhanced customization options, improved energy efficiency, and more sophisticated control systems. These innovations will further cement the kubba machine's position as an essential tool in modern food processing operations.

Market Expansion and Adaptation

As global appreciation for Middle Eastern cuisine grows, the demand for kubba machines continues to expand beyond traditional markets. Food processors and restaurants worldwide are recognizing the equipment's versatility and potential for adaptation to various culinary applications. This broadening market creates opportunities for manufacturers to develop specialized versions catering to different regional preferences and requirements.

The increasing focus on sustainability in food production may drive further innovations in kubba machine design, such as reduced water consumption and improved energy efficiency. These developments will help businesses meet growing environmental responsibilities while maintaining operational efficiency.

Frequently Asked Questions

What capacity range can kubba machines handle?

Kubba machines are available in various sizes, with production capacities ranging from 500 to 3000 pieces per hour, depending on the model and configuration. Commercial units typically offer adjustable output rates to accommodate different production requirements.

How does maintenance affect machine longevity?

Regular maintenance, including daily cleaning, component inspection, and scheduled service intervals, can significantly extend a kubba machine's operational life. Most manufacturers recommend professional servicing every 6-12 months, depending on usage intensity.

Are kubba machines suitable for small businesses?

While industrial kubba machines are designed for high-volume production, manufacturers now offer compact models suitable for small businesses and restaurants. These smaller units provide the same quality and consistency benefits while requiring less space and initial investment.