Transforming Commercial Kitchen Efficiency with Modern Automation

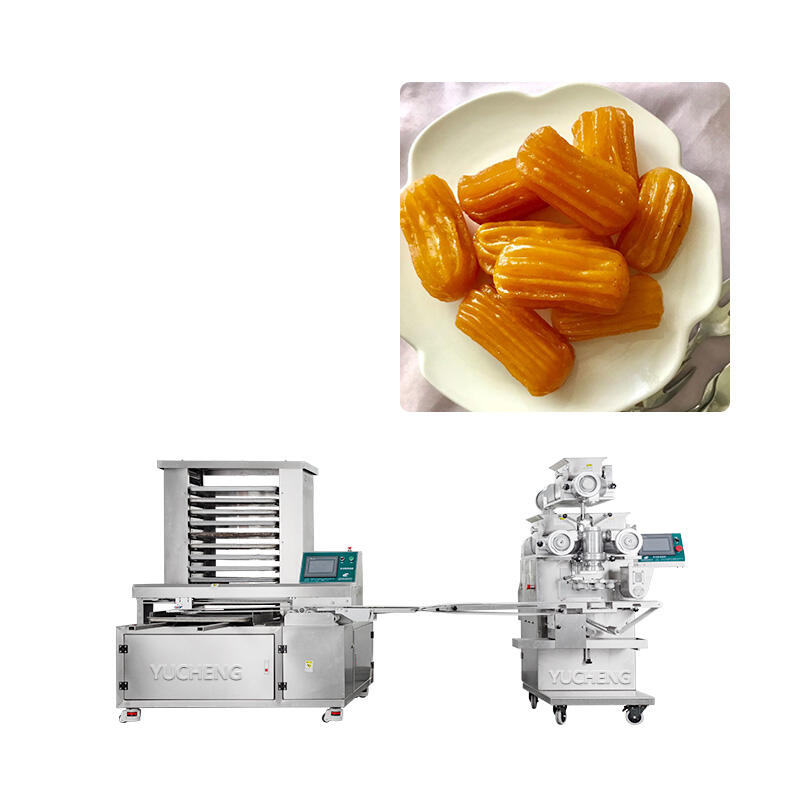

The culinary world is witnessing a remarkable transformation as innovative technologies reshape traditional food preparation methods. At the forefront of this revolution is the kubba machine, a groundbreaking piece of equipment that's changing how commercial kitchens approach Middle Eastern cuisine preparation. This sophisticated device has become an indispensable tool for restaurants, catering services, and food manufacturing facilities looking to streamline their operations while maintaining authentic taste and quality.

Professional kitchens are constantly seeking ways to optimize their workflow without compromising on food quality. The kubba machine addresses this challenge head-on by automating one of the most time-consuming aspects of Middle Eastern food preparation - crafting perfectly shaped kubba, kibbeh, or kibbe with consistent quality and remarkable efficiency.

Understanding the Kubba Machine Technology

Core Components and Functionality

The kubba machine is an engineering marvel designed specifically for the mass production of traditional Middle Eastern stuffed dumplings. Its sophisticated mechanism comprises several key components: a mixing chamber for combining bulgur wheat and meat, a precision forming system for the outer shell, and an innovative filling mechanism that ensures perfect distribution of the stuffing. The machine's digital controls allow for precise adjustments to size, thickness, and filling ratios, ensuring consistent results with every batch.

Advanced models feature variable speed settings, allowing operators to adjust production rates based on their specific needs. The automated cleaning systems and removable parts make maintenance straightforward, while built-in safety features protect both operators and the quality of the final product.

Production Capacity and Efficiency

When it comes to production capabilities, the kubba machine truly shines. A single unit can produce hundreds of perfectly formed kubba per hour, dramatically outpacing manual preparation methods. This increased output doesn't just save time - it transforms the entire kitchen workflow by freeing up staff for other essential tasks while maintaining consistent quality throughout the production run.

The precision of the machine ensures minimal waste of ingredients, leading to better cost management and improved profit margins. Additionally, the consistent size and shape of machine-produced kubba result in more predictable cooking times and better portion control.

Operational Benefits in Commercial Settings

Time and Labor Optimization

The introduction of a kubba machine into a commercial kitchen setting creates immediate and measurable improvements in operational efficiency. Traditional manual kubba preparation requires skilled staff and considerable time investment, often limiting production capacity and increasing labor costs. With the automation provided by the kubba machine, kitchens can redirect their workforce to other valuable tasks while maintaining or even increasing production volume.

Labor savings extend beyond just the preparation phase. The consistency in size and shape leads to standardized cooking times, making it easier to train new staff and maintain quality control across different shifts or locations. This standardization is particularly valuable for restaurants with multiple branches or catering operations serving large events.

Quality Control and Consistency

One of the most significant advantages of utilizing a kubba machine is the unprecedented level of consistency it brings to food preparation. Every piece produced has identical proportions of shell to filling, ensuring a uniform cooking process and consistent customer experience. This standardization is crucial for businesses building their brand around reliable quality and authentic taste.

The machine's precise control over ingredients and portion sizes also helps maintain food cost calculations and nutritional information accuracy. This level of control is increasingly important in today's market, where customers are more conscious about portion sizes and nutritional content.

Economic Impact and Return on Investment

Cost Analysis and Savings

Investing in a kubba machine represents a significant upfront cost, but the return on investment typically becomes apparent within the first year of operation. The reduction in labor costs alone often justifies the investment, particularly in high-volume operations. The machine's precision in ingredient usage reduces waste, while its speed increases production capacity, allowing businesses to meet higher demand without proportional increases in operating costs.

The durability and reliability of modern kubba machines mean maintenance costs are relatively low, especially when compared to the ongoing costs of manual preparation. Additionally, the consistency in product quality helps reduce waste from improperly formed or damaged items, further contributing to cost savings.

Market Expansion Opportunities

The efficiency and consistency provided by a kubba machine open new market opportunities for food businesses. The increased production capacity allows for expansion into wholesale markets, catering services, or frozen food production. Many businesses find they can introduce new product lines or variations of traditional kubba once they have the reliability and speed of machine production.

The standardization of product quality also makes it easier to establish partnerships with other food service businesses or retail outlets, as consistent quality and supply can be guaranteed. This scalability aspect is particularly valuable for businesses looking to grow their market presence or expand into new territories.

Frequently Asked Questions

How long does it take to master operating a kubba machine?

Most operators can become proficient with basic machine operations within 1-2 days of training. However, achieving optimal efficiency and understanding all features typically takes about a week of regular use. Manufacturer-provided training programs can significantly accelerate this learning curve.

What maintenance does a kubba machine require?

Regular maintenance includes daily cleaning of food contact surfaces, weekly deep cleaning of removable parts, and monthly inspection of mechanical components. Most manufacturers recommend professional servicing once or twice a year, depending on usage volume.

Can a kubba machine accommodate different recipes and variations?

Modern kubba machines are highly versatile and can be adjusted to work with various recipes and filling types. Most models allow for modifications in shell thickness, filling ratios, and overall size, making them suitable for different regional variations and specialty products.