Revolutionizing Commercial Bakery Operations with Advanced Equipment

The modern bakery landscape has undergone a remarkable transformation with the integration of pastry making machines. These sophisticated pieces of equipment have become the backbone of successful commercial bakeries, fundamentally changing how pastries are produced at scale while maintaining the delicate balance between efficiency and quality. From small artisanal bakeries to large-scale production facilities, pastry making machines have proven instrumental in meeting growing consumer demands while upholding the highest standards of consistency and taste.

The evolution of pastry making machines represents a significant leap forward in food production technology. These machines combine precision engineering with innovative features to streamline the complex process of pastry creation. By automating crucial steps that traditionally required extensive manual labor, these machines have not only increased production capacity but also enhanced the consistency of the final product – a feat that even skilled pastry chefs find challenging to achieve through manual methods alone.

Core Components and Functionality of Modern Pastry Equipment

Essential Mechanical Systems

At the heart of every pastry making machine lies a series of sophisticated mechanical systems designed for specific functions. The dough handling system ensures proper mixing and kneading, while precise temperature control mechanisms maintain optimal conditions throughout the production process. The layering system, particularly crucial for items like croissants and Danish pastries, creates the characteristic flaky texture through automated folding and laminating processes.

Advanced models feature programmable controls that allow operators to fine-tune various parameters such as mixing speed, resting time, and folding cycles. These adjustable settings ensure that each type of pastry receives the exact treatment needed for optimal results, eliminating the variability that often occurs with manual processing.

Automated Control Features

Modern pastry making machines incorporate smart technology that provides unprecedented control over the production process. Digital interfaces allow operators to store and recall specific recipes, ensuring consistency across different batches. Sensors monitor critical factors such as dough temperature, humidity, and consistency, making real-time adjustments to maintain ideal conditions.

The integration of automated control systems also enables better resource management. These machines can calculate precise ingredient quantities, reducing waste and ensuring cost-effective production. The ability to maintain exact specifications throughout the process results in consistently high-quality products that meet both aesthetic and taste requirements.

Enhanced Production Efficiency and Output

Speed and Volume Optimization

The implementation of a pastry making machine dramatically increases production capacity. What once took hours of manual labor can now be accomplished in a fraction of the time, without compromising quality. These machines can process large volumes of dough continuously, maintaining consistent quality throughout extended production runs.

The enhanced speed doesn't just mean faster production – it translates to better business opportunities. Bakeries can take on larger orders, diversify their product range, and respond more quickly to market demands. The ability to scale production up or down as needed provides valuable flexibility in meeting varying customer requirements.

Labor and Resource Management

By automating labor-intensive tasks, pastry making machines allow bakeries to optimize their workforce allocation. Staff members can focus on more specialized tasks such as product development, quality control, and customer service, rather than spending hours on repetitive manual processes. This reallocation of human resources often leads to improved overall operational efficiency and better utilization of skilled personnel.

The precision of automated systems also results in significant reduction in material waste. Exact portioning and consistent processing mean fewer rejected products and better use of raw materials. This efficiency extends to energy consumption as well, with modern machines designed to optimize power usage during operation.

Quality Control and Consistency Advantages

Precision in Production

One of the most significant benefits of using a pastry making machine is the unprecedented level of consistency it brings to the production process. Each piece of pastry receives identical treatment, from the initial mixing to the final shaping, ensuring uniform quality across entire batches. This consistency is particularly valuable for businesses building their brand on reliability and quality.

The precision extends to portion control and sizing, resulting in pastries that not only taste the same but look identical – a crucial factor for commercial operations and retail presentation. This standardization helps in maintaining pricing structures and managing customer expectations effectively.

Quality Monitoring Systems

Modern pastry making machines come equipped with sophisticated monitoring systems that track various quality parameters throughout the production process. These systems can detect and alert operators to any deviations from set standards, allowing for immediate corrective action. This proactive approach to quality control helps maintain high standards while minimizing product waste.

The integration of quality monitoring systems also facilitates compliance with food safety regulations. Automated logging of production parameters provides valuable documentation for quality assurance purposes, while consistent processing helps maintain hygiene standards.

Frequently Asked Questions

What maintenance requirements do pastry making machines have?

Regular maintenance for a pastry making machine includes daily cleaning of all food contact surfaces, weekly deep cleaning of mechanical components, and scheduled professional servicing every 3-6 months. Proper maintenance ensures optimal performance, longevity of the equipment, and compliance with health regulations.

How long does it take to train staff on using a pastry making machine?

Training time typically varies between 1-2 weeks for basic operations, with additional time needed for advanced features and troubleshooting. Most manufacturers provide comprehensive training programs and ongoing support to ensure operators can fully utilize the machine's capabilities.

What types of pastries can be produced with an automated machine?

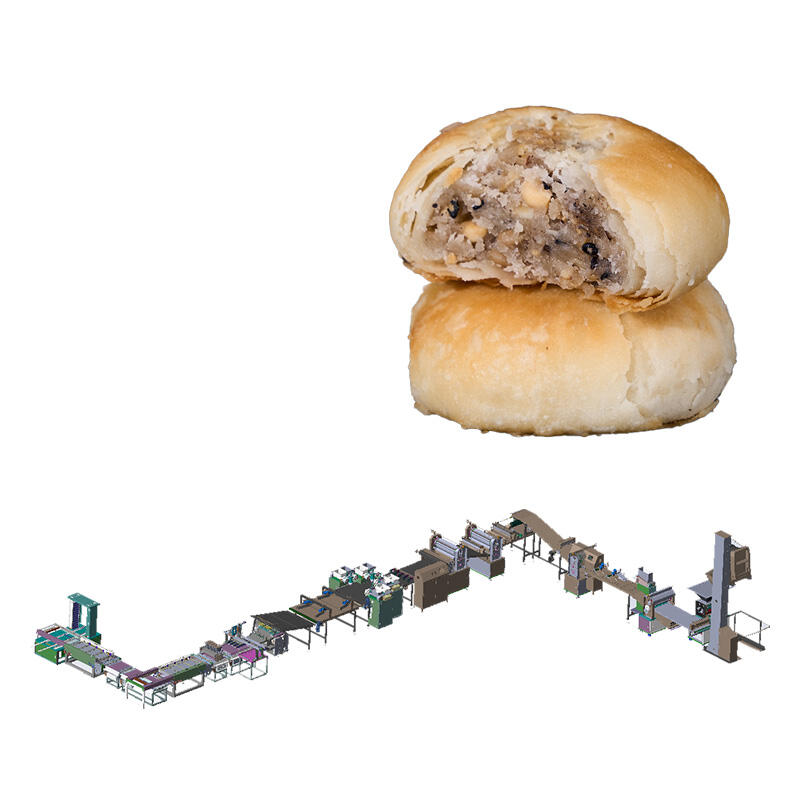

Modern pastry making machines are versatile and can produce a wide range of items including croissants, Danish pastries, puff pastry products, laminated dough items, and various filled pastries. Many machines offer customizable settings to accommodate different recipes and styles of pastry.