protein ball making machine

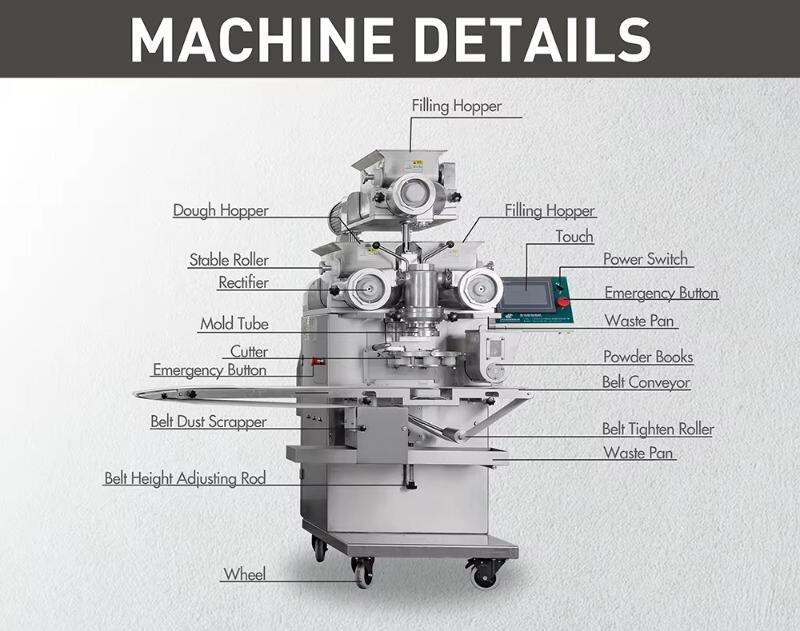

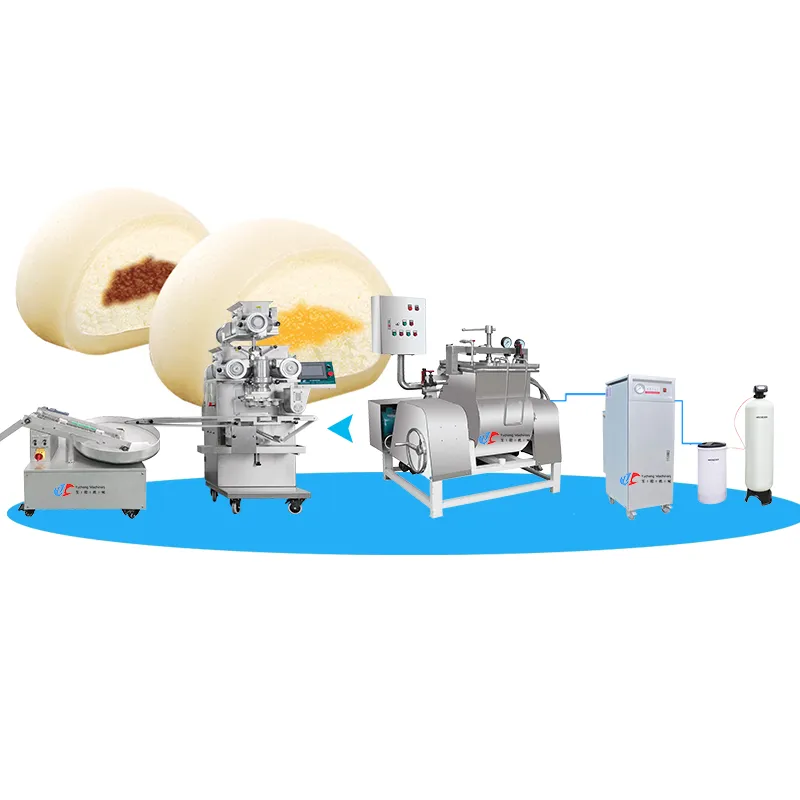

The protein ball making machine represents a revolutionary advancement in food processing technology, designed to efficiently produce uniform, high-quality protein balls at scale. This sophisticated equipment combines precision engineering with user-friendly operation to streamline the production process. The machine features an advanced mixing system that ensures consistent blending of ingredients, followed by a precise portioning mechanism that creates perfectly sized balls every time. Its stainless steel construction meets strict hygiene standards, while the automated control panel allows operators to adjust parameters such as size, density, and production speed. The machine can process various protein-based ingredients, including whey, pea, and soy proteins, along with additional components like nuts, seeds, and natural sweeteners. With production capabilities ranging from 500 to 2000 pieces per hour, it caters to both small-scale manufacturers and large industrial operations. The integrated temperature control system maintains optimal conditions throughout the process, ensuring product consistency and quality. Advanced safety features, including emergency stop buttons and protective guards, guarantee operator safety while maintaining high productivity levels.