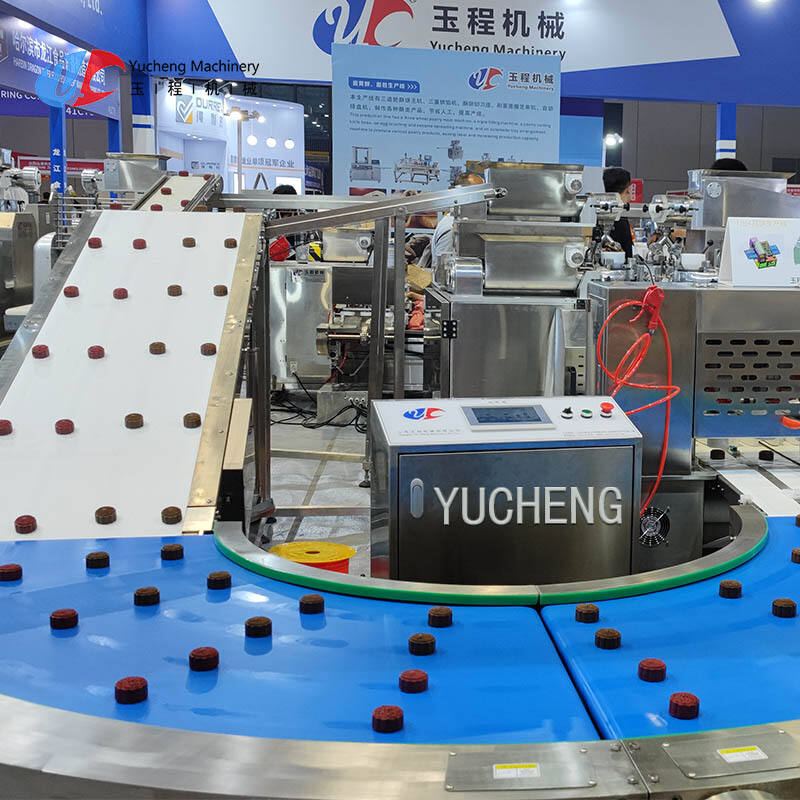

multi row date bar machine

The multi row date bar machine represents a significant advancement in food processing technology, designed specifically for efficient and precise date bar production. This sophisticated equipment can simultaneously process multiple rows of date bars, dramatically increasing production capacity while maintaining consistent quality. The machine features advanced extrusion technology that carefully processes date paste into uniform bars, complete with customizable size and shape options. Its stainless steel construction ensures durability and meets strict food safety standards, while the integrated cooling system helps maintain optimal temperature during production. The machine's automated feeding system seamlessly handles date paste input, while precision cutting mechanisms ensure uniform bar sizes. Notable technological features include digital control panels for precise parameter adjustment, variable speed controls for production optimization, and automatic synchronization between different processing stages. The equipment is suitable for various production scales, from medium-sized food manufacturing facilities to large industrial operations. Its versatile design allows for processing different types of date varieties and can be adapted for other fruit-based products. The machine's efficient cleaning system and easy-to-maintain components minimize downtime and ensure consistent production quality.