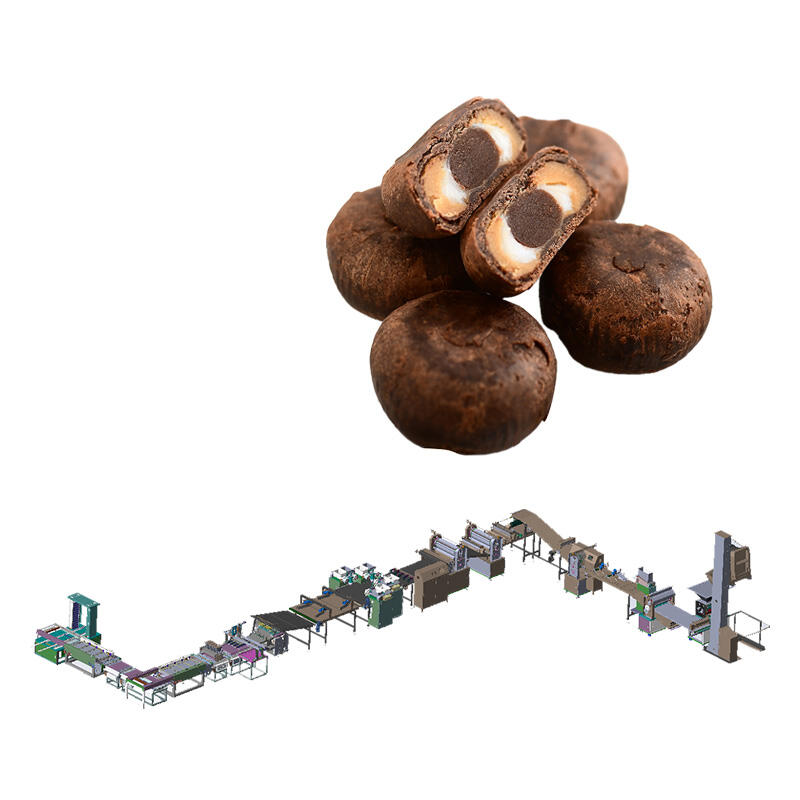

industrial cookie machine

An industrial cookie machine represents a cornerstone of modern bakery production, combining precision engineering with advanced automation to deliver consistent, high quality baked goods at scale. These machines feature state of the art technology, including programmable controls that allow for precise adjustment of temperature, timing, and dough handling parameters. The system typically comprises multiple components: a mixing unit that ensures thorough ingredient blending, a forming mechanism that shapes cookies with remarkable consistency, and a continuous band oven that provides even baking across the entire production line. Advanced models incorporate smart sensors that monitor dough consistency, temperature variations, and product quality in real time. The machines can handle various dough types, from traditional butter based to complex textured varieties, while maintaining uniform size, shape, and weight across batches. Production capabilities often range from 1,000 to 15,000 cookies per hour, making them suitable for medium to large scale operations. Modern industrial cookie machines also feature user friendly interfaces, allowing operators to easily switch between different recipe settings and monitor production metrics.