biscuit extruder

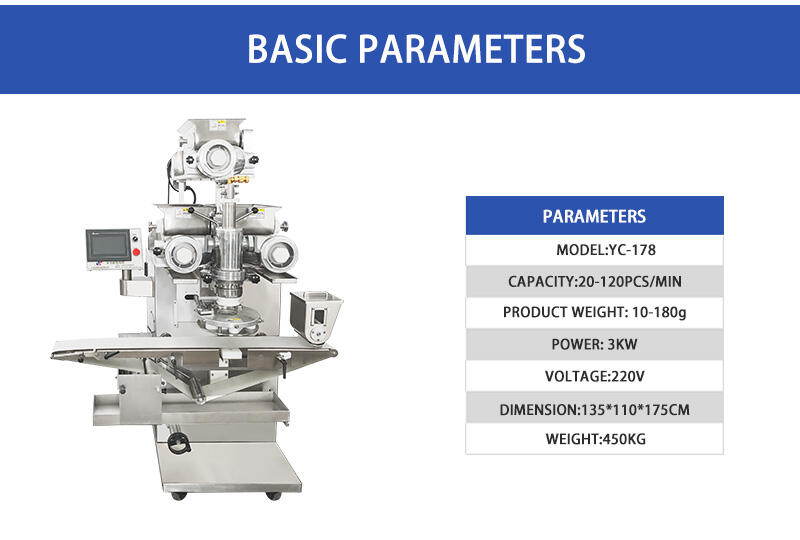

A biscuit extruder is a sophisticated piece of food processing equipment designed to efficiently produce various types of biscuits and cookies through a continuous extrusion process. This versatile machine combines mixing, kneading, and shaping capabilities in one unified system, streamlining the production process while ensuring consistent quality output. The extruder features a robust mechanical structure with a powerful motor that drives the extrusion mechanism, coupled with precision temperature control systems that maintain optimal dough consistency. The machine incorporates advanced servo-driven wire-cutting mechanisms that ensure precise portion control and shape formation, while its modular design allows for quick recipe changes and cleaning procedures. The extrusion system utilizes specially designed dies that can be easily interchanged to create different biscuit shapes and patterns, offering manufacturers the flexibility to produce diverse product lines. Modern biscuit extruders are equipped with digital control panels that enable operators to monitor and adjust critical parameters such as speed, temperature, and pressure in real-time, ensuring optimal production conditions and consistent product quality. These machines are capable of handling various dough formulations, from traditional butter cookies to complex multi-textured biscuits, making them indispensable in both artisanal bakeries and large-scale industrial production facilities.