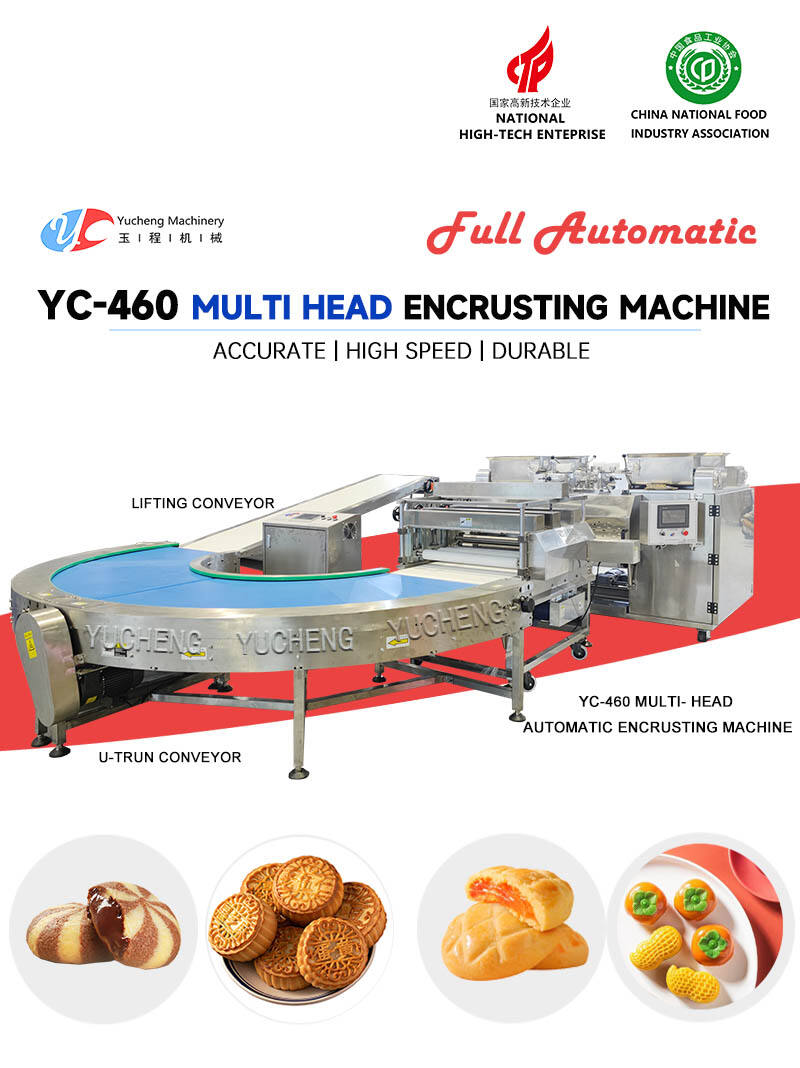

commercial cookie press machine

A commercial cookie press machine is an advanced culinary equipment designed to streamline the production of consistently shaped cookies and pastries in commercial settings. This sophisticated device combines precision engineering with user-friendly operation, enabling bakeries and food service establishments to produce large quantities of uniform cookies efficiently. The machine typically features a robust stainless steel construction, incorporating a high-capacity hopper that can hold substantial amounts of dough. Its mechanical or pneumatic pressing system delivers precise pressure control, ensuring each cookie maintains identical shape and size. The machine often includes interchangeable dies and nozzles, allowing for various design patterns and shapes. Advanced models feature digital controls for speed adjustment, pressure regulation, and production timing, maximizing output while maintaining quality. Many units are equipped with automatic cutting mechanisms and conveyor systems, facilitating continuous production flow. Safety features include emergency stop buttons, guard rails, and overload protection. These machines can typically produce hundreds of cookies per hour, making them ideal for industrial bakeries, large restaurants, and food manufacturing facilities. Modern versions often incorporate easy-clean designs with removable parts and sanitization-friendly surfaces, ensuring compliance with food safety standards.