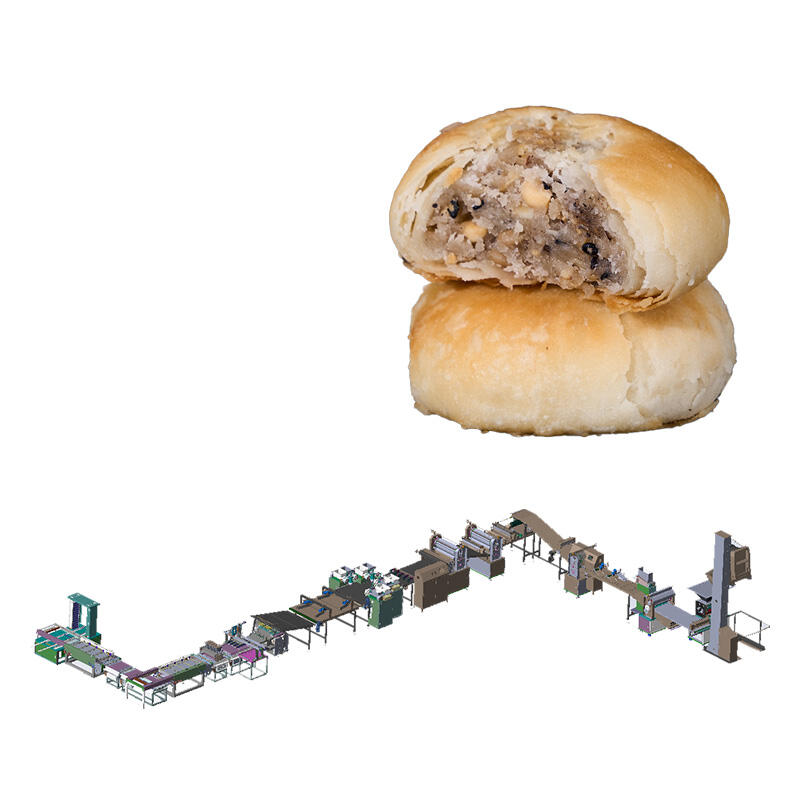

bakery product making machine

The bakery product making machine represents a revolutionary advancement in commercial baking technology, offering a comprehensive solution for producing various baked goods with precision and efficiency. This versatile equipment combines mixing, kneading, shaping, and baking capabilities in a single integrated system. The machine features state-of-the-art digital controls that allow operators to program and store multiple recipes, ensuring consistency across production batches. Its stainless steel construction guarantees durability and meets strict hygiene standards, while the modular design facilitates easy cleaning and maintenance. The machine can handle various dough types, from soft bread doughs to stiff cookie batters, with adjustable speed settings and temperature controls. Advanced features include automated ingredient dispensing, precise temperature monitoring, and intelligent timing systems that optimize the baking process. The equipment's capacity can be scaled to meet different production needs, making it suitable for both small bakeries and large-scale industrial operations. Safety features such as emergency stop buttons and overload protection ensure operator security, while energy-efficient components reduce operational costs.