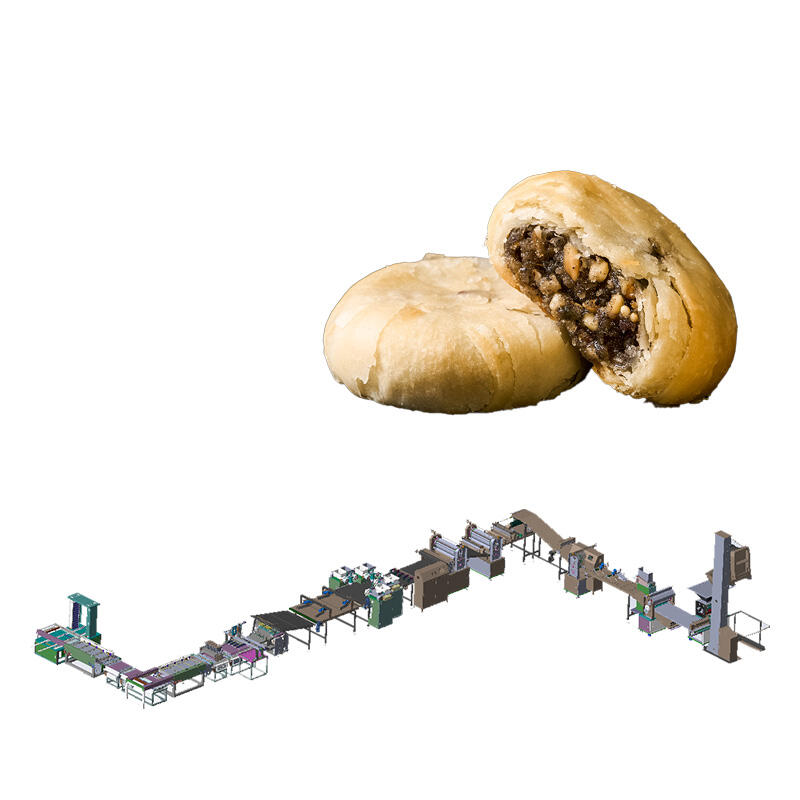

commercial bread making machine

Commercial bread making machines represent the pinnacle of modern bakery automation, combining efficiency with consistency in professional food service operations. These robust systems feature advanced dough mixing mechanisms, precise temperature controls, and programmable baking cycles that ensure perfect results every time. The machines typically incorporate multiple stages of bread production, from initial mixing and kneading to proofing and final baking, all within a single unit. With capacities ranging from 15 to 100 loaves per hour, these machines can meet diverse production demands. They come equipped with digital control panels that allow operators to adjust parameters such as mixing speed, proofing time, and baking temperature. Advanced models include features like automatic ingredient dispensing, customizable recipe storage, and self-cleaning functions. The machines utilize energy-efficient heating elements and insulated baking chambers to maintain consistent temperatures while minimizing energy consumption. Safety features such as emergency stop buttons, overheating protection, and secure door locks ensure operator protection. These machines are designed for continuous operation in commercial settings, featuring durable stainless steel construction and easy-to-maintain components that withstand the rigors of daily use.