bread manufacturing machine price

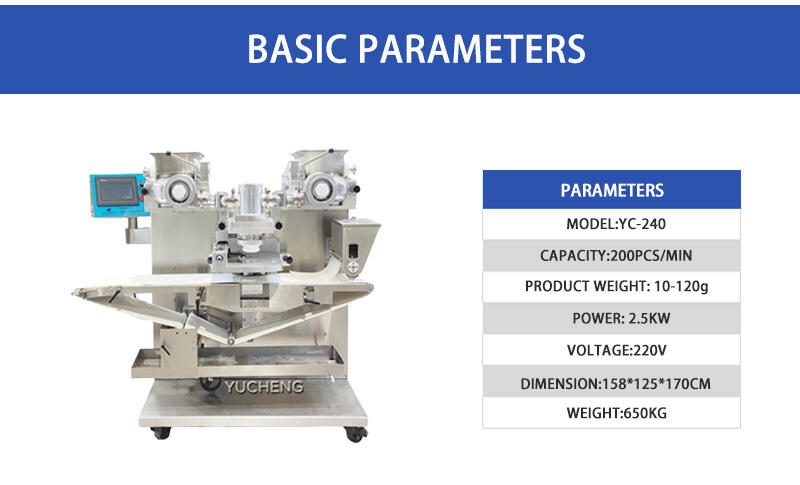

When exploring the bread manufacturing machine price market, potential buyers encounter a range of options that reflect various capabilities and production scales. Modern bread manufacturing machines typically range from $5,000 to $50,000, with prices varying based on capacity, automation level, and additional features. These machines integrate multiple functions including mixing, kneading, proofing, and baking, streamlining the entire bread production process. Advanced models feature programmable controls, energy-efficient systems, and automated cleaning mechanisms, making them ideal for both industrial bakeries and medium-sized operations. The price points correlate directly with production capacity, ranging from 100 to 1,000 loaves per hour, and technological sophistication, such as touch-screen interfaces and remote monitoring capabilities. Cost considerations should also factor in energy efficiency ratings, maintenance requirements, and warranty coverage. Many manufacturers offer flexible financing options, making these essential pieces of equipment more accessible to businesses of various sizes. The initial investment in a bread manufacturing machine often translates to significant long-term savings through reduced labor costs, consistent product quality, and improved production efficiency.